Weave Stainless Steel Mesh

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Hebei

-

Validity to:

Long-term effective

-

Last update:

2021-10-21 01:10

-

Browse the number:

215

+

- Contactaixin:

weierpusi(Mr.)

-

Email:

telephone:

phone:

-

Arrea:

Hebei

Address:Room 403, De'ao Building, Hehuang Road, Anping County, China

- Website:

+

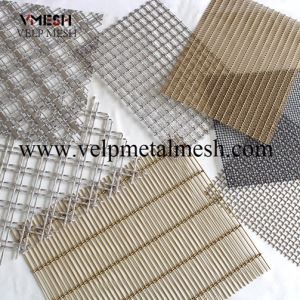

At some stage of production, many industries needs to sieve, screen or grade their raw materials or products. In support of this, there is nothing quite as superior as woven wire mesh as a filtration medium. It is a highly durable material, being both resistant to corrosion and very strong. Mesh also offers excellent open areas. Likewise, it is supplied in many specifications. We also supply stainless steel woven mesh for many other uses .

Weave Style :

The Product Range

We maintain huge stocks of mesh. Rolls of woven wire stainless steel mesh are readily available in a wide range of mesh specifications. We keep stocks with a mesh count from 2 mesh (with a 1.6 mm wire diameter) through to 500 mesh (with a 0.025 mm wire diameter). These provide apertures from 11.1 mm down to 0.025 mm (25 microns). Primarily of stainless steel, woven wire mesh stocks are also held in a range of other materials. These include mild steel, brass, phosphor bronze, copper, monel, aluminium . Furthermore, we stock Type 304 and Type 316 stainless steel mesh in most specifications.Types of Weave

Mesh can be woven in several ways. The largest demand is for plain weave woven mesh. For the finer meshes, twilled weave woven mesh is available from our stocks. We also supply plain dutch and twilled dutch weaves. Of note, the dutch weaves allow for the finest filtration, down to 0.006 mm (6 microns).

Types of Weave

Mesh can be woven in several ways . The largest demand is for plain weave woven mesh. For the finer meshes, twilled weave woven mesh is available from our stocks. We also supply plain dutch and twilled dutch weaves. Of note, the dutch weaves allow for the finest filtration, down to 0.006 mm (6 microns) .

Material:

Plain steel, stainless steel(304, 316, 316L), aluminum, copper, brass, bronze, etc.

Features:

Heat resisting,Corrosion resisting, Acid resisting

Applications:

Mainly used for filtering and sieving, extensively used in petroleum, chemical industry, environment protection, mine, airspace, paper-making, electronic, metallurgy etc.

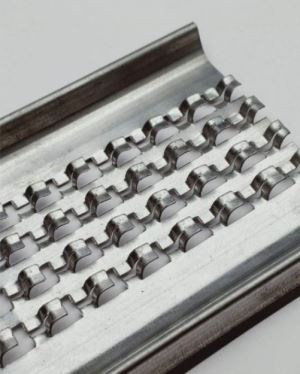

This weave permits a heavier wire diameter to be used than would be possible in a plain weave wire mesh with similar mesh count.

General industrial use |

Mining |

Quarrying |

Beer brewing |

Water filtration |

Particle separation |

Automotive |

Basket fabrication |

Refinery & oil field |

Aerospace |

Food processing |

Scientific & laboratory use |

Material Choose:

SS304 wire mesh

304 stainless steel is the most widely available of all stainless steels in the wire mesh industry. Aside from the countless combinations of mesh opening sizes and diameter wire available both from stock and through manufacturing, 304SS exhibits many benefits and is largely considered the standard of the industry. T-304 SS has excellent corrosion resistance in a wide range of environments and is used in a wide range of applications.

Some of the more popular applications and industries that use 304 stainless steel are listed below:

SS316 Wire Mesh

316 stainless steel is recognized as the second most widely available of all stainless steels in the wire mesh industry. 316 stainless steel wire mesh is typically considered an alternative grade to 304 stainless steel wire mesh and preferred in certain circumstances. Particularly, in marine environments and in applications requiring heavy welding, 316 stainless steel is commonly specified due to its many benefits.

316 stainless steel has excellent corrosion resistance, and in particular, performs well in its ability to resist pitting and crevice corrosion in warm chloride environments. The inclusion of molybdenum (Mo) is a major factor for the improved corrosion resistance compared to a 304 stainless steel counterpart.

While 304 stainless steel wire mesh is generally more popular and more readily available in a wide array of specifications, 316 stainless steel wire mesh is often used and found in applications and industries highlighted below:

Marine technologies |

Pharmaceuticals |

Boat & yacht fittings |

Food preparation & processing |

Rubber, plastic machinery |

Scientific & laboratory use |

Chemical processing |

Automotive |

Refinery & oil field |

Aerospace |

Particle separation |

General industrial use |

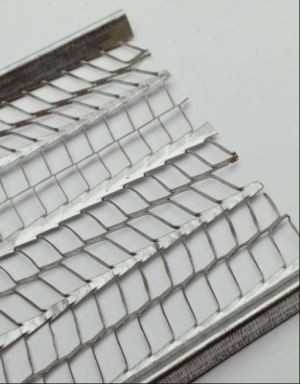

Packing

To protect the mesh surface, usually we pack 200 micro stainless steel wire mesh with:

Paper pipe inside of the mesh --> then waterproof paper --> moist proof paper --> bigger paper pipe --> poly-wood carton.

Or we can pack as per your request.

http://www.velpmetalmesh.com/